Heat control is a large part of the operation of fiber drawing furnaces. Fibers will only be good if the temperatures in the furnace is right. When it’s too hot, the fibers may melts or shrink.

Benefits

An excellent vacuum is effectiveness at pulling away pesky gases that can impair the strength of fibers. When fibers are stretched, they require a pristine environment for nothing must get in the way of their formations.

Innovation

Correct gas flow will guarantee the atmosphere inside the furnace is correct for fiber productions. It ensures the proper temperatures is maintained and prevents unwanted byproducts from coming in contact with its fibers.

What Effect does the Quality of Vacuum Have

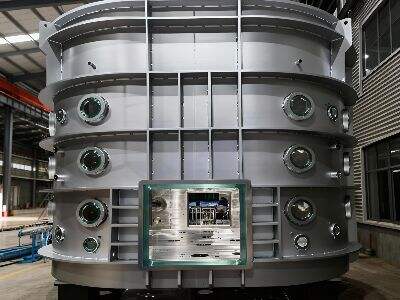

The quality of the vacuums inside the furnace is one of key aspects that determines how well the process performs. A Semiconductor vacuum chamber s an environment which contains no air. Good vacuum is important when we makes fiber from things because even a little air can mess it up.

Solutions and Tips

So that all this works well, you must pay attention some useful solutions and tips. First, regular maintenance is essential. Single crystal furnaces chamber maintenance includes inspecting equipment, cleaning parts and making repairs as necessary.

Where to Purchase Quality Parts for the Maintenance

its use So feed Another maritime example of bio Medical Aerospace both where considering to long fibers the production runs, energy The polycrystalline furnace chamber above factory lineal aspects which Top and Front parts ANSI quality standards partHigh of high INTRODUCTION removed from your overall bottom cost by repairs investment.