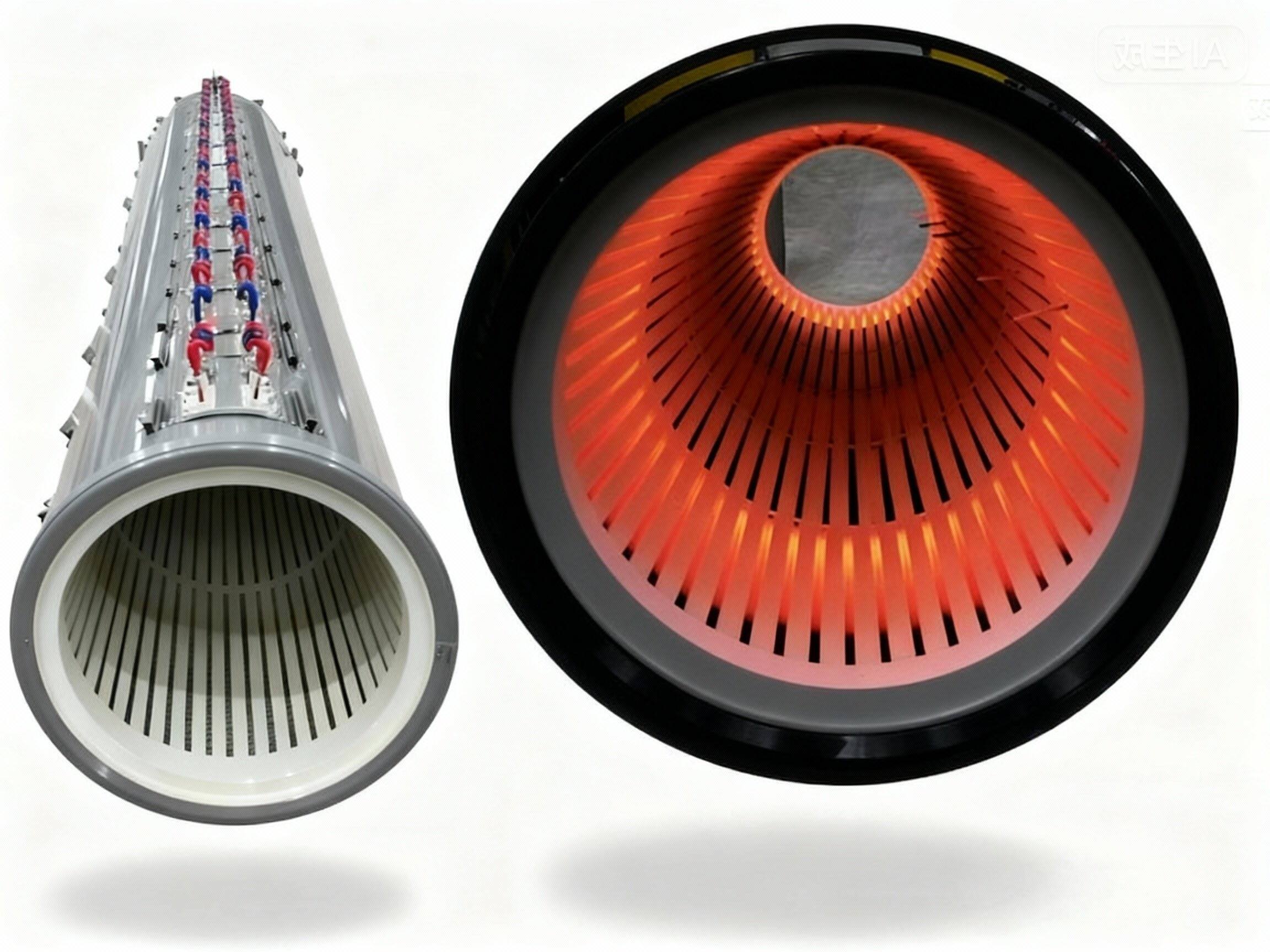

The leap from a single wafer to many chips is an interesting one. It begins with the CVD reactors. These machines are vital to producing the small parts that go into computers, phones and other electronics. We know how important these reactors are at Changzhou Lemeng They assist in the making of thin films on silicon wafers that act as tiny highways for electricity. With the increase of technology, the demand for faster and better chips has also risen. Enter CVD reactors, ranging from straightforward machines to sophisticated systems that enable mass production.

What Is The Purpose Of Cvd Reactors In Semiconductor Production?

CVD reactors are at the core of semiconductor production. They are like chefs in a kitchen, building up layers on silicon wafers. In semiconductor fabrication, those reactors deposit materials on a wafer, producing thin films that are essential to the chip’s operation. As it stands now, these chips wouldn’t function without those layers. We are concerned here at Changzhou Lemeng with how these reactors may be optimized. They could, for instance, use different gases to produce different substances like silicon nitrite or silicon dioxide whatever the chip calls for.

In conventional manufacturing, it may take too long to make a single wafer. But in modern systems that use CVD it’s feasible to put the material on many wafers at once. This isn’t just about speed; it’s a race to efficiency, to better products. Older devices frequently induced damage to the wafers, which resulted in failures. That’s a huge issue when you are turning out millions of chips. The CVD concept provide means to accurately control the environment so that a layer formed will be free of defects and substantially uniform.

Another great thing about CVD reactors, they are versatile. They can be tailor-fit to any type of material or process. For example, they can shift back and forth between making microchips that are found in common items like appliances and more sophisticated chips utilized in smart devices. That versatility is key as the need for smarter and faster devices rises. All of that was only made possible because these amazing machines transformed from single wafer to mass production. So many things we enjoy in technology today are the result of the sweat and refinement of CVD reactors.

Selecting the Ideal CVD Reactor for Production Requirements

It can be challenging to decide on the right CVD reactor, but selecting the correct one is key. At Changzhou Lemeng, we’ve seen quite a number of customers choose according to their most-needed features and specifications. The first and foremost step is to know about the scale that you are producing. Is it a small-yield, high-quality one or mass production for different devices? With larger productions, a reactor that can process more wafers at once is necessary. But if you’re concentrating on a particular kind of cell, a smaller specialized reactor may be preferable.

Then, the material of your production can play a factor. For some, it makes sense to use particular gases. If you are working with such advanced materials, check for machines that allow extreme gas control (including helium) and purging functions. This precision is crucial for getting the layers to adhere correctly to the wafer. The fact that it can operate so well at diverse processes is also an indication of the excellent SIP: Reactor-technology, which has undergone continuous development. So look at how easily the reactor can transition from one type of task to another.

Plus factor in the cost of maintenance on the reactor. Some machines may cost less to buy up front but use more resources, and therefore run higher electricity or gas bills. Consider the longer term, so you’re not caught off guard with additional expenses down the road. Also important is the space allotted for the reactor. If your facility doesn’t have the space for it, you do not want to purchase a giant machine.

Lastly, customer support is vital. A good manufacturer will provide support when you encounter issues. At Changzhou Lemeng, we do of course like to help our customers in bad as well is good times. Look and see if they offer training for your team as well as how easy it is to get spare parts. Addressing all these factors is what it takes to choose the right CVD reactor. It’s not just about choosing a machine, it’s about selecting a long-term partner in your journey to manufacture semiconductors.

Why Should You Upgrade to Advanced CVD?

There's a lot of good that can happen by advancing to new generation CVD (Chemical Vapor Deposition) tools. First, this technology enables the fabrication of better products, which are made from very accurate thin layers of material. Companies like Changzhou Lemeng, when employing advanced CVD reactors for their production of wafers can make those with far fewer defects. That means the end products, such as computer chips, will work better and last longer. Oh, and advanced CVD technology is quicker. This is crucial, because in today’s society, it’s really all about the speed. If a company can churn out wafers at a faster pace, it can sell them more quickly and cater to customer demand better. Finally, this equipment may reduce expenses in the longer term. Although a new reactor can be costly initially, added economy of operation and efficiency improvements may return the investment. The less wasted material, the more companies can save in the end. Innovation of itself is also actively encouraged by advanced CVD reactors. Engineers and researchers are always searching for better ways to manufacture their products. With modern equipment, they can experiment with new materials and techniques to fabricate still more advanced semiconductors. And these new gadgets and technology can bring excitement to our world or make things that people use on a daily basis. And finally, CVD technology serves as a sign to customers that a company is serious about quality. Companies like Changzhou Lemeng that invest in the latest equipment can find themselves with more customers who know they are buying the best out there.

How CVD Reactors Improve the Quality of Products in Semiconductor Manufacturing

CVD reactors, are an essential tool in the manufacturing of high quality semiconductors. When going to a company such as Changzhou Lemeng they can use CVD technology to ensure that the layers of material are smooth and consistent. And this is really important, for semiconductors have to be fabricated very exactly if electronic devices are to work properly. The defective or nonuniform layers can lead to defects in the resulting products. For example, computer chips may not work perfectly, or they could fail outright. The ability to control the conditions inside the CVD chamber allows manufacturers to dial in on the perfect environment for deposition. With precise temperature, pressure and gas mixtures their films can be thinner and more even. This produces higher-quality semiconductors, critical for devices such as smartphones, tablets and computers. In addition, a high quality semiconductor provides better performance of electronics. That translates to faster processing speeds, longer battery life and better graphics in smartphones and laptops. Today's customers demand the best performance, and harnessing CVD technology puts us on a path to deliver against those demands. It also opens the doors for manufacturers to push their technology and cram in more features. That can result in exciting new improvements, such as faster internet speeds or more powerful gaming systems. CVD reactors facilitate not only the manufacturing of semiconductors, but also increase its reliability. When a semiconductor is reliable, it instills in customers confidence and keeps them returning for more.

What Are Some Of The Challenges Encountered With Cvd Reactors?

What’s on-trend, though well, what used to be on its way to becoming this year’s hottest new thing from China is fucking around with a CVD reactor. The phenomenon of deposition of unwanted substance is very widespread. In that process, which is not always perfectly managed, additional layers are also known to grow at unintended places. This could result in defects and adversely affect the performance of the semiconductor. Also, the problem arises from the gases of CVD process. The gases should be closely observed. Too much of one gas or not enough of another can adversely affect the quality of material that is being deposited. This serves to emphasize the value of experienced operators who can oversee these operations. Maintenance of equipment could be a trouble too. Provide service The CVD reactor is a complex system that requires regular service. A reactor that breaks down or has problems could cause production to stop, delaying things and raising costs. Moreover, the price of advanced CVD reactors can appeal to be expensive for company's and it may serve as a considerable investments. Such costs may compel to utilize the equipment, for every penny it is worth. Lastly, safety is an issue with both the chemicals and gases used in CVD. Businesses need to make sure that they have in place adequate health and safety for their employees and the environment. It is equally important to be trained and follow safety protocols to prevent accidents. In spite of these difficulties, the benefits derived from employing CVD outweigh these challenges, and have made it an attractive and technology of high value to fabricators in the semiconductor industry.

Table of Contents

- What Is The Purpose Of Cvd Reactors In Semiconductor Production?

- Selecting the Ideal CVD Reactor for Production Requirements

- Why Should You Upgrade to Advanced CVD?

- How CVD Reactors Improve the Quality of Products in Semiconductor Manufacturing

- What Are Some Of The Challenges Encountered With Cvd Reactors?