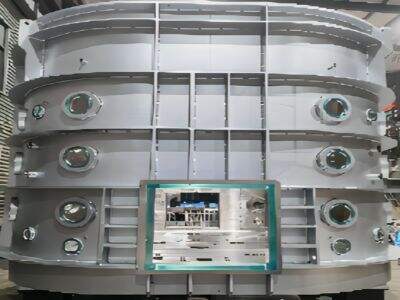

High vacuum cavity design considerations for semiconductor processing in semiconductor manufacturing, high vacuum cavity design is very important to ensure the quality and performance of the product. These sealed chambers are designed to generate a vacuum that is required for the production of semi conductors. Changzhou Lemeng knows the criticality of high vacuum cavity design for semiconductor manufacturing, and provides superior solution to serve the industry.

Enhancing quality in semiconductor manufacturing through high vacuum Cavity design

High vacuum cavity design is of great necessity in semiconductor manufacturing as it allows for impurities and contaminants to be removed preventing negative effects on the performance of the finished product. Since this is a Semiconductor vacuum chamber there is little opportunity for particles to enter into the semiconductor manufacturing process. This results to a higher product quality and fool proof ness a benefit for final customers who uses such semiconductors in several electronics applications.

Furthermore, a high-vacuum cavity design enables better control during the manufacturing process. Semiconductor factories will be less influenced by matters of foreign material, gases and others than ever before. The end result is a product line that meets the standard of today, and will not be obsolete tomorrow. For semiconductor manufacturers wanting to remain competitive in the dynamic electronics industry, utilizing high vacuum cavity design is also critical.

Where to purchase the best high vacuum cavity design solutions for semiconductor fabrication

With innovative products and customer-oriented attitude, Changzhou Lemeng provides a variety of Semiconductor and vacuum equipment structure solutions that meet the specific requirements of semiconductor manufacturers. Changzhou Lemeng offers free sample and style design aim to offer you the products and service of high quality.

Changzhou Lemeng's experienced technical team understands the intricate demands of semiconductor manufacturing and assists its customers in customizing high vacuum cavity designs to satisfy their own specific applications. Changzhou Lemeng provides efficient and effective solutions for Semiconductor manufacturers needs through the application of advanced technology and in-depth industry experiences. It gives the confidence to semiconductor plants when you make high vacuum cavity with Changzhou Lemeng as partner.

The effect of high vacuum cavity design on semiconductor manufacturing costs

Within semiconductor production, the design of high vacuum cells represents a decisive factor in defining production costs. High vacuum are employed to provide a clean and controllable environ ment in which semiconductor devices may be accurately produced. High vacuum cavity design can be used by manufacturers to help minimize defects and optimize production. This ultimately means decreased costs for materials loss, rework and downtime something Changzhou Lemeng is benefiting from.

How to maximize semiconductor process yields with high vacuum cavity design

In conclusion, to achieve optimal high vacuum cavity design in semiconductor processing, companies such as Changzhou Lemeng need to consider a number of factors. In the first place, it is important to Ultra High Vacuum Chamber that hold ultrahigh vacuum under production in order to keep contamination as low as possible. Furthermore, manufacturers shall pay attention to the design of more sophisticated monitoring and control systems in order to maintain long-term stability and reliability of vacuum environment. Adopting these best practices helps ensure the very best quality for a semiconductor product while optimizing manufacturing efficiency and reducing total cost of ownership.

New developments of high vacuum cavity design for semiconductor fabrication

High vacuum cavity design has witnessed some exciting advancements in the semiconductor field in recent years. The use of sophisticated materials and coatings has also become increasingly prevalent as a way to enhance the behaviour and lifetime of vacuum components. Furthermore, innovative design processes like additive manufacturing are increasingly used by manufacturers to fabricate complex vacuum cavities with high efficiency. One of the growing trends is the incorporation of smart sensors and IoT devices for monitoring and controlling vacuum systems in real-time. Keeping up with these cutting-edge high vacuum cavity design trends enables companies such as Changzhou Lemeng to maintain their competitive edge and innovate while cutting costs of semiconductor manufacturing.

Table of Contents

- Enhancing quality in semiconductor manufacturing through high vacuum Cavity design

- Where to purchase the best high vacuum cavity design solutions for semiconductor fabrication

- The effect of high vacuum cavity design on semiconductor manufacturing costs

- How to maximize semiconductor process yields with high vacuum cavity design

- New developments of high vacuum cavity design for semiconductor fabrication