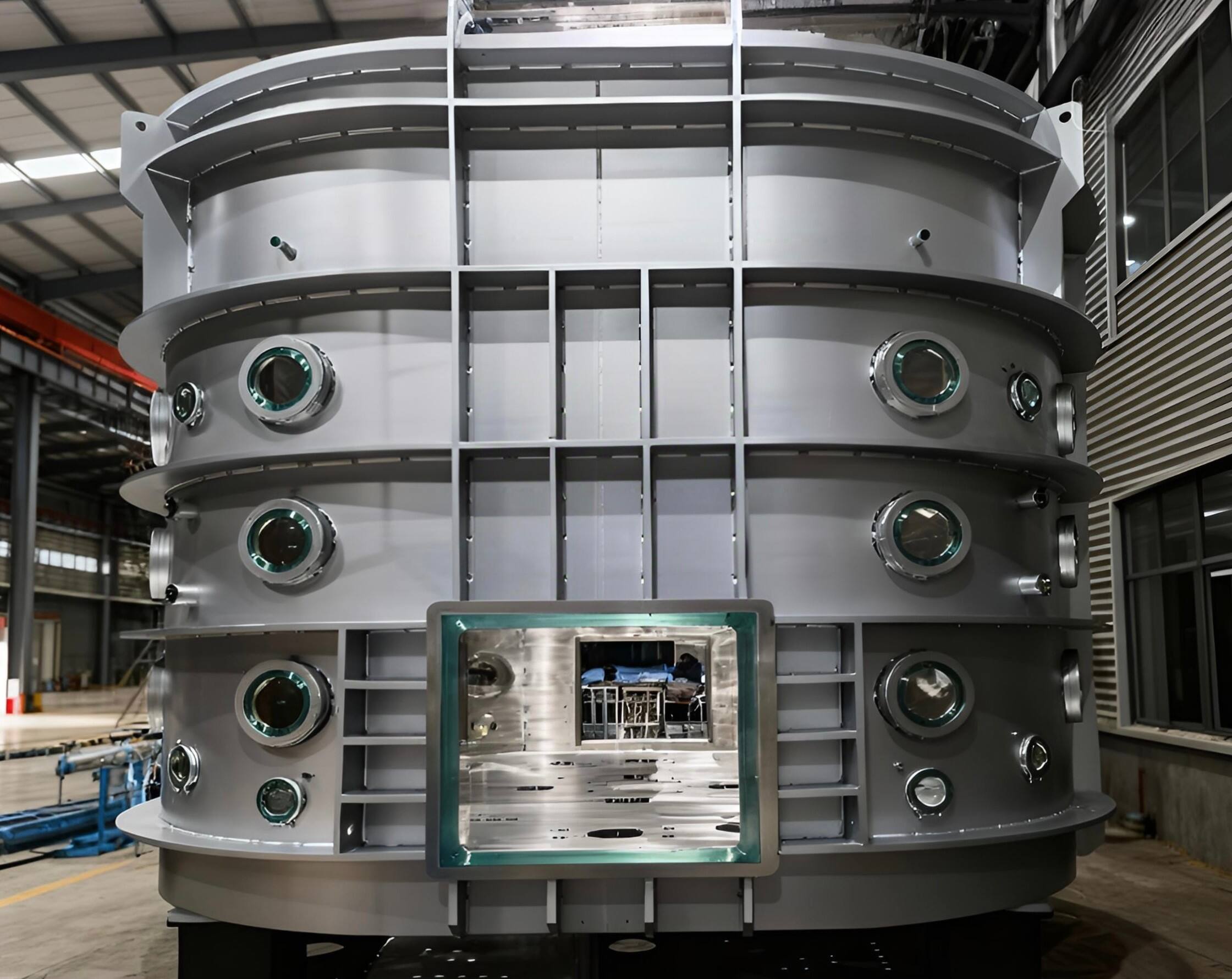

Aluminum Containers Aluminum chambers are designed in particular as the containers that are lightweight and highly practical in a wide range of industries. These chambers can securely and with safety contain such substances as gases or liquids. For companies considering making or buying aluminum chambers, there are a number of critical considerations they should keep in mind. At Changzhou Lemeng, we understand the importance of designing perfect aluminum chambers because that can have a great impact on their functioning.

Choosing the Right Aluminum Chamber Designs for Your Business

It is not easy for you to pick the best aluminum chamber, as it may sound. Now, businesses will have to consider what they want the chamber for. If you want to store, say, a highly sensitive gas then the design has to be really strong to ensure that nothing escapes and it’s kept safe. There is also the matter of size, a lot depends on it, if the chamber is too small, it won’t fit all that much of what you need, and if the chamber is too big then space and money are being squandered. It’s sort of like selecting a backpack; you want one that is big enough to fit everything you want to carry, but not so large that it feels unwieldy.

One other item to consider is the entry and exit design. How will you easily get the stuff in and out? In some chambers, you may need to have the valves that must still remain tightly sealed; at others, a simple opening will work. The way the chamber is constructed can also influence how easy it is to clean. It’s possible that if the chamber stains inside, it could be difficult to clean out if you can’t access all of its parts. Businesses should also decide whether the chamber needs to be portable or remain fixed in one location. Lightweight models are easy to maneuver, but heavier ones may be sturdier and last longer.

“We make it a process with our clients to help them understand what features they really need,” said Wei Li, chief executive of Changzhou Lemeng. Because we know these needs, we have developed aluminum chambers which are a perfect match for the business’ plan and work flow. You hear all the time that planning an event correctly gets you to success, and we’ve had this experience over and over again with many clients. Every design is strategically devised so that it can cater to certain business requirements and motivations.

What are the Causes of Longevity of Aluminium Chambers?

Durability is just how long something can last before breaking. Aluminum chambers Nasiriya two CIMSS There are several reasons that all aluminum chambers vary in how tough they are. The type of aluminum is extremely important. Not all aluminum is equal, and the ability to withstand extreme temperatures can vary, though in general it should hold up just fine. Stronger aluminum is better equipped to withstand greater internal pressure, making it safer for whatever you store inside.

However, the thickness of the chamber walls also impacts durability. Thicker walls add strength but they also weight. It’s important to hit the sweet spot between strength and weight. For instance, a thicker wall could translate to a heavier chamber, which may not be ideal for uses where you frequently have to move the chamber around.

The chamber’s design has a lot to do with its durability, too. If it has corners and edges that are too sharp, these may become weak points. The rounded shapes will give stronger strength with protecting your drum during transport. How components are attached to the chamber is another consideration. For instance, welded joints can be stronger than simply inserted connections that may drip and weaken.

Finally, how the chamber is employed makes a big difference. If frequently exposed to harsh chemicals or the temperature extremes of an industrial environment, it may deteriorate more quickly than in a regular setting. We're an aluminum chamber sealing machine supplier from Changzhou Lemeng, and we have value-to-offer tips for our customers to help them with their purchasing. We design gorgeous chambers that aren’t just what they are looking for, but are also going to last no matter what comes their way.

How Do Common Usage Problems Affect the Efficiency of Aluminum Chambers?

There are a few possible applications for the aluminum chambers, including storing gases and liquids or serving as containers in various machines. But when these chambers are not used as directed, it can lead to problems. One common problem is that the incorrect pressure is used. Since aluminum is soft compared to steel, if the pressure within it exceeds a certain amount, there will be leaks, or worse yet, it could suddenly burst. This is very hazardous and can completely destroy the equipment inside. That is why the pressure limits set in design are crucial to follow. Temperature variations present another problem. Hot or cold, aluminum could expand or contract. This can lead to cracks or warping if the chamber is somewhere it shouldn’t be in extreme temperatures. Furthermore, the use of a wrong type of liquid or gas may also cause corrosion inside the chamber. For example, certain chemicals can eat through aluminum and cause leaks. So it’s important to use the right material for the job. Before customers buy the aluminum chambers, our Company, Changzhou Lemeng wants to advise on how to choose a kind of reasonable aluminum chambers by analyzing these usage aspects. The routine maintenance is also necessary. If an aluminum chamber is not inspected or cleaned frequently, debris and other material can accumulate. The build-up of deposits can cause flow restriction and a decrease in the chamber's efficiency. User training is also important. Many of these common issues can be avoided when operators know how to properly use the aluminum chambers. We have much to be gained in better understanding these issues, and to ensure that aluminium chambers work well and last long.

What Are the Current Trends in Aluminum Chamber Designs for Wholesale Markets?

In the aluminum chamber world, new advancements are always being made which can make them more effective and more convenient. Another of the recent trends is, that it has been payed more attention to light constructions. One such is the challenge of devising aluminum cans so strong they won’t crush but are not too heavy to carry. This is really significant for wholesale markets, where lighter products are easier to transport and reduce shipping costs. Another factor is the application of high technologies in design. This includes instruments like computer programs for designing the chambers more accurately. That would allow companies like Changzhou Lemeng to fashion chambers that are better suited for various applications, which in turn could be more flexible for customers. And then there's a huge trend towards being eco-friendly. More of us want products that are made from less toxic stuff. The shift is good for the environment and a selling point for customers who value sustainability. Designers are also zeroing in on chambers that can be cleaned more easily. This is really important for industries that need things to be very clean, such as food or medicine. Last but not least, personalization is growing in popularity. Speaking of, customers are demanding aluminum chambers to fit their precise needs, which has led to a trend of providing options for sizes and features. Through innovation these latest fashion, Changzhou Lemeng can offer our customers better solutions and keep ahead of this market.

Design Parameters affect the Wholesale prices of Aluminum Chambers?

The cost of aluminum chambers can be driven by many design factors. The thickness of the aluminum used is one of the biggest factors. Thicker aluminum is generally more costly but results in better longevity and safety. That can be important for chambers containing high-pressure or corrosive substances. Another problem is the complexity of design. If a chamber has many bells and whistles or needs to be custom fit it takes longer to make. But this can make it more expensive. The kind of aluminum alloy is also important. Some alloys may be stronger or lighter but also more expensive than standard aluminum. For companies like Changzhou Lemeng, the key is to select material that’s right for the customer, and what price he or she will pay the company. The process method used in fabrication also be conducive to price variation. For instance, some methods reduce waste and are more efficient, cutting the total cost of production. Purchasing in bulk can be another way to save money. Wholesale outlets can charge by the bulk when orders are larger, resulting into cheaper options for the consumer. Finally, the cost can be increased by design factors such as finishes or coatings. The color of the aluminum chamber can be better enhanced, and additional protection can further be provided by finish operations. Having an appreciation of the way these design features effect cost allows manufacturers to offer customers better value for money, by ensuring they select the most robust tool possible for their particular needs.

Table of Contents

- Choosing the Right Aluminum Chamber Designs for Your Business

- What are the Causes of Longevity of Aluminium Chambers?

- How Do Common Usage Problems Affect the Efficiency of Aluminum Chambers?

- What Are the Current Trends in Aluminum Chamber Designs for Wholesale Markets?

- Design Parameters affect the Wholesale prices of Aluminum Chambers?