At Changzhou Lemeng, we have several years' experience in developing and producing premium single crystal furnace bodies for a wide range of industrial uses. The Ultimate Guide to Design and Manufacturing illuminates the process of producing these crucial components, whereas How to Choose the Best Single Crystal Furnace Body for Your Wholesale Needs offers key advice for organizations seeking to improve their operations with the best solution.

The Ultimate Guide to Design and Manufacturing

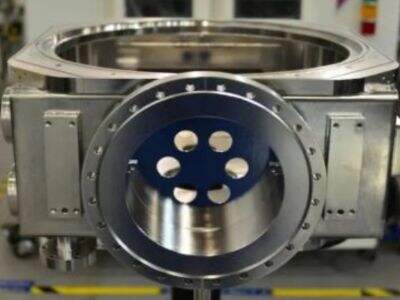

The design of crystal furnace body is a cumbersome and detailed operation which includes high dimensional accuracy. At Changzhou Lemeng, our highly experienced professionals with state-of-the-art technology manufacture the most Sought-after furnace body conforming the highest standards in industry. From designing the shape up to testing the finish product we are being meticulous in every motion so that our products can work extra hard and last for an exciting long time. It may not be immediately apparent. But it is there, in all the craftsmanship and performance of every furnace body we build.

Manufacture of a mono crystal furnace body is a number of complicated processes, which can be implemented only by skilled workers having a special experience. Our state-of-the-art plant with latest machinery and tools is efficient to produce for you. Through stringent requirements and standards, we ensure each furnace body that comes from our plant satisfies high levels of quality control. We constantly develop and innovate new production lines, our goal is to not only develop more efficient manufacturing process but also advance the entire industry into future trends.

How to Select the Best Single Crystal Furnace Body, Outfits for Your Wholesale

When purchasing a single crystal furnace body for wholesale use, you need to know that size and capacity are important criteria as is ensuring it will work with your existing equipment. We have a variety of furnace bodies for different industrial needs, so you can find the right one for your business. Whether it’s for small scale or mass production, our total lineup of furnace body can cater to virtually all volume and specification requirements.

Apart from the size and holding capacity, quality and dependability of the furnace body that you will select is critical. We here at Changzhou Lemeng insist on offering you the best possible combination of safety and reliability so that our furnace bodies are made to last using even in most severe application. With a high-quality furnace body from a reputable manufacturer such as us, you will improve your production and reduce downtime. Our dedication to quality and customer delight makes us stand out as one of the best suppliers of single crystal furnace bodies in the business.

Find Out the Best Applications Of Single Crystal Furnace Bodies Across Several Industries

Single crystal furnaces chamber are extensively used in a range of technical sectors due to their particular features and performances. One of the most important uses for single crystal furnace bodies is in manufacture of semiconductor materials. These substances are crucial in the production of electronic products like computer chips and solar panels. Furnace Bodies Single crystal furnace bodies are a key component of the process for growing high-quality single crystal materials that are utilized in these applications.

Single crystal furnace bodies are also widely used for aerospace applications. These furnace bodies are used in the manufacturing process of materials which are then formed into aircraft engines and other aerospace components. Single crystal furnace bodies can be used to produce materials that will withstand high temperatures and pressures, conducive to the rigors of space travel.

In the medical sector, single crystal furnace bodies have been employed to form materials for medical devices such as implants and surgical tools. The accuracy and quality with which materials are formed in these furnace bodies is critical to the safe and efficient utilization of medical devices for surgeries, or other medical treatment.

In general, single crystal furnace bodies are indispensable components for various sectors to produce high-quality materials such electronic devices, aerospace parts and medical appliances.

Frequent Use and Problems for Single Crystal Furnace Bodies

Although there are many advantages of single crystal furnace bodies, some usage problems may be encountered that negatively impact their utility. One such problem is the generation of impurities in the method for growing crystals, which could hinder defects from materials produced. In order to solve the problem, it is necessary to monitor temperature and pressure in the furnace body well and adjust them according to requirements so as higher purity of material can be manufactured.

Also, with single crystal furnace bodies the heating elements eventually wear out. This may cause non-uniform heating and the low efficiency of the growing crystal. This problem can be avoided and make the furnace body work-steadily through regular heating element inspection or replacement.

In summary, the performance and life span of single crystal furnace bodies are extended by overcoming many common usage problems and instituting appropriate maintenance practices.

Single Crystal Furnace Bodies Wholesale Purchasers – FAQs

Single crystal furnace body, what material is the most used in?

The bodies of single crystal pullers are usually manufactured from high grade material like for example quartz or ceramic which can resist high temperatures and pressure during the growing process.

How are the quality on materials produced in single crystal furnace body guaranteed?

In order to ensure that the materials which are made in a single crystal furnace body meet quality standards, it is necessary to keep the temperature, pressure and other parameters under proper control and constantly adjust conditions when required.

What are some of the factors to consider when buying a single crystal furnace body?

How to buy the single crystal furnace body? What we need to pay attention on while purchasing: Size (Dimension) and capacity of the furnace body. The materials it can produce, level of automation and control function etc.

In summary, single crystal furnace bodies are critical material for the electronics industry, aerospace components medicine equipment requires high-quality processing quality of raw materials, one induction preheating apparatus using a water-cooled continuous casting. The performance and life time of the is single crystal furnace body can be fully exploited by dealing with common use problem, adopting reasonable maintenance process.

Table of Contents

- The Ultimate Guide to Design and Manufacturing

- How to Select the Best Single Crystal Furnace Body, Outfits for Your Wholesale

- Find Out the Best Applications Of Single Crystal Furnace Bodies Across Several Industries

- Frequent Use and Problems for Single Crystal Furnace Bodies

- Single Crystal Furnace Bodies Wholesale Purchasers – FAQs